Composites and Their Impact on Workforce Safety

By Kyle Pollino, Sales Manager, OSCO Safety

I recently had the opportunity to speak at the Alleghenies Regional Safety Conference, a wonderful gathering designed to help industrial operations improve the quality of their safety programs. It was an honor to be asked to present on how the choice of materials for safety structures plays an important role in both the performance and longevity of safety solutions.

First and foremost, industrial safety is about protecting people. It’s also about protecting property and helping companies get the most from their investment. At OSCO Safety, we believe so strongly in safety that we put it right in our name. The article that follows is a condensed version of my presentation on how today’s composite materials provide unmatched safety benefits for a variety of industrial applications.

What is Composite Material?

A composite is made by combining two or more materials to form a new material. Some of the most common composites seen in everyday life are concrete, carbon fiber and the fiberglass-reinforced plastics used to replace wood in decking applications. For the purposes of industrial safety structures, the composite material of choice is fiberglass-reinforced polymer (FRP).

Why are more industrial applications choosing FRP over traditional steel and aluminum materials? FRP is more cost-efficient and durable, but it really comes down to one word: safety.

Safety and Other Benefits of Composites

Chemical plants. Power generation. Warehouses. Wastewater treatment. The list of manufacturing facilities and industrial applications goes on and on and includes a vast range of businesses. Common to them all is the need for safety structures, maintenance access and other solutions that keep people out of harm’s way.

Most facilities include moving equipment, heat, moisture, chemicals and other hazards. In the old days, wooden structures quickly warped, rotted, or worse, caught fire. They were replaced by steel structures, which provided strength but were heavy and subject to rust and corrosion. Aluminum provided some corrosion resistance, but it easily dents and bends. Like steel, it also conducts electricity. A better solution was needed to reduce safety risks and increase durability, and that’s where composites come in.

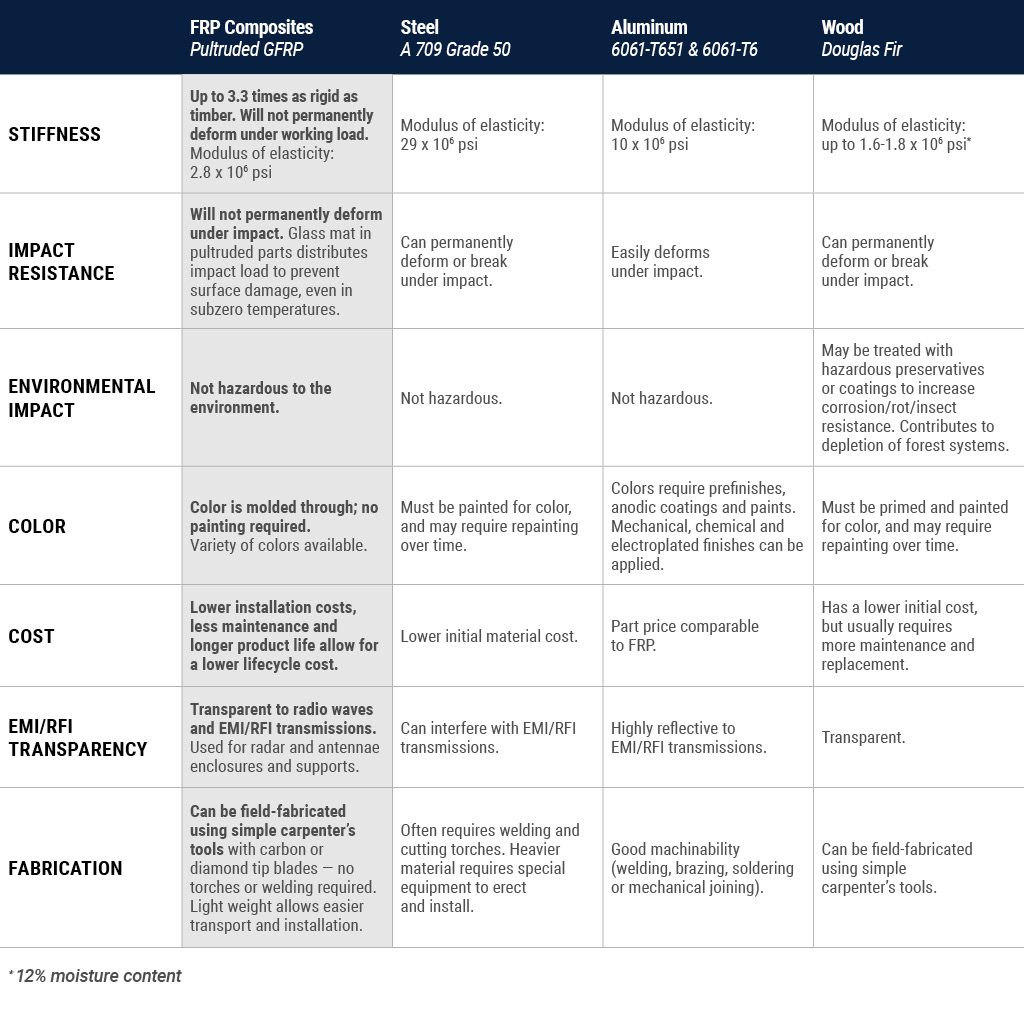

This chart compares composites to steel, aluminum and wood.

By taking a look at each characteristic, it’s easy to see the benefits of composite materials.

- Weight. Composites are able to provide the strength of steel and aluminum at considerably less weight. There’s an obvious cost savings because less substructure materials are needed to handle the weight, plus the materials are easier to maneuver for installation. That can mean simple handling rather than requiring a forklift or crane. In terms of safety, the lighter weight plays a big role. The National Safety Council estimates that 25% of all workplace injuries come from manual lifting, and the Bureau of Labor Statistics claims that 36% stem from shoulder and back injuries caused by overextension, overexertion or overuse. The lighter weight of composites greatly reduces that risk. It helps keep people safe and helps keep them on the job.

- Thermal Properties. As mentioned, many manufacturing facilities have equipment that generates heat, and humidity can be an issue in a range of applications. When steel heats up and when condensation forms, people are at risk of burns and slips. Heat can also cause aluminum to bend, creating a tripping hazard. Composites have low thermal properties, so they don’t absorb heat and are less likely to create hazards due to expansion.

- Electrical Conductivity. One of the most serious safety hazards to human life in the workplace is the risk of an electric shock. A wire touching a metal structure is all it takes. Composites are nonconductive, greatly increasing safety. In addition, installation costs can be lower because they don’t need to be grounded.

- Corrosion, Rot & Insect Resistance. Composites resist chemicals, moisture and insects. This is important for safety because it helps maintain structural integrity. Rusted, corroded metal and rotted wood will weaken and fail. In addition, significant maintenance costs are saved. While rusting steel requires constant sanding and repainting, and while wooden boards need to be replaced, composites require little to no maintenance.

- EMI/RFI Transparency. The use of chips, barcodes and radio waves are common in a variety of applications. Aluminum and steel can cause interference. Composites do not.

- Impact Resistance. This is a big deal for safety. According to OSHA, slips, trips and falls cause 15% of all accidental deaths, and injuries from them account for 12 to 15 percent of all workers’ compensation claims — costing employers approximately $40,000 per incident. Ordinary foot traffic can create dings and dents in aluminum and wood, and dropped tools and equipment can damage steel. These dents are permanent and are a leading cause of trips and falls. Composites will not deform from impacts, substantially reducing the risk of workplace accidents.

- Fabrication. Metals can have sharp edges and often require the use of welding or other specialty equipment for installation. Composites are easier to handle, won’t splinter like wood, and can be adjusted onsite and installed using ordinary tools. Installation costs are reduced, as is injury risk.

Another safety advantage of composites that isn’t on the chart is slip resistance. Anti-slip surfaces can be built directly into the composite during manufacturing, so there’s no risk of an applied material such as non-slip tape coming off. The safety yellow coloring is also integrated throughout, so it can’t be scraped off over time like yellow paint on metals or wood.

Safety Solutions Built to Last

A safety structure is an investment. You want to save people while also saving money, and you want to ensure your safety solutions last so that you don’t have to keep pouring money into them.

Composites check every box. They provide the strength required and have endless configurations to meet any application need. Installation is cost-efficient, and there are little to no maintenance costs. Best of all, they don’t require ongoing replacement because the many safety features, especially corrosion resistance, ensure long-term performance.

At OSCO Safety, we can help you find the ideal solution for protecting your business and your people. We’re the exclusive supplier of ReadySeries FRP components, a modular system of composite platforms, rails, ladders and more that can be configured as needed without the expense of a custom order. From stair treads and crossovers to marking flags and safety signs, we have it all. Contact us today to discuss your safety needs.

Learn More

Yes, we’ll be happy to sell you some safety solutions. But mostly we just want people to be safe. That’s our mission, and we support it with a library of information you can use to better understand OSHA requirements, safety solutions and more. Here are a few topics you may wish to review:

This page includes a video on OSHA requirements for handrails and guardrails.

This page features several videos, including configuring platforms and crossovers, a time lapse of a platform assembly and a look at what it’s like to work with OSCO.

Proactive Ways to Avoid OSHA Violations

This video and article include several steps you can take to protect your business.

Again, please contact us for more information, to discuss your project or to schedule an onsite safety assessment with an OSCO Safety expert.