Additional Information

Handle The Toughest Jobs

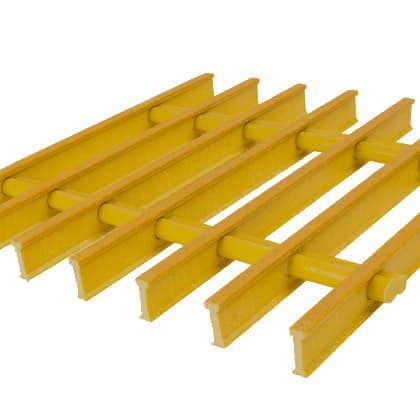

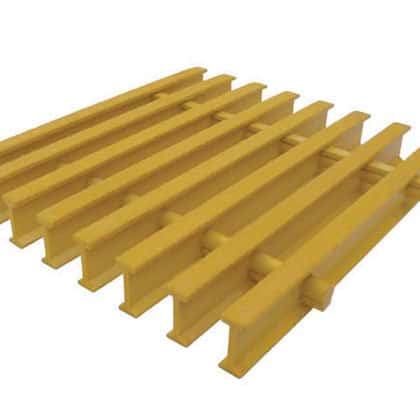

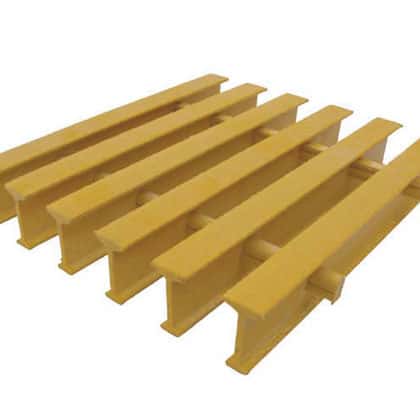

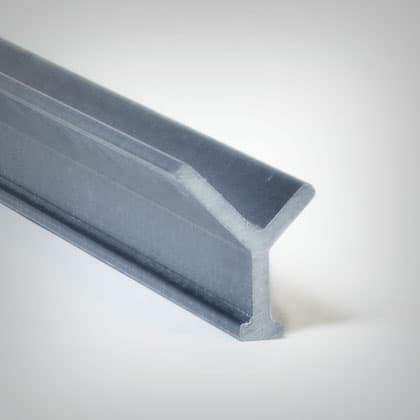

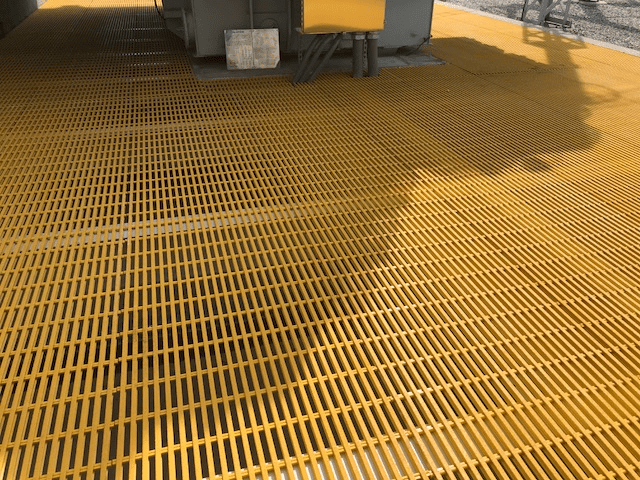

Whether you need stair treads that can handle constant traffic, walkways that cover a long span, trench covers that hold up under vehicular weight, or platforms with high load demands, pultruded fiberglass grating is the right choice. Available in a variety of grating patterns, the bar shape in FRP pultruded grating is reinforced with glass rovings for durability. Bearing bars and cross rods lock mechanically to deliver maximum unidirectional strength.

The Pultrusion Process

FRP pultruded grating gets its high strength not only from the combination of glass rovings, glass mat and vinyl ester resins, but also from the pultrusion process itself. Consisting of more glass than resin, pultruded fiberglass grating is fabricated by pulling fiberglass roving through a pultrusion machine. To ensure high strength in all directions, rolls of woven fiberglass mat provide multidirectional reinforcement while creels of fiberglass roving provide unidirectional strength along the length of the profile. The grating is formed using load bars kept parallel by a series of cross rods. The fiberglass then receives a resin bath and gets wrapped with a surfacing veil made out of fiberglass strands. The result is bar grating with the high strength to handle any application.

For applications with short spans or where ultra-high strength isn’t needed, OSCO also carries a complete line of molded gratings.

Advantages Of Pultruded Fiberglass Grating

Highly Stable & Strong

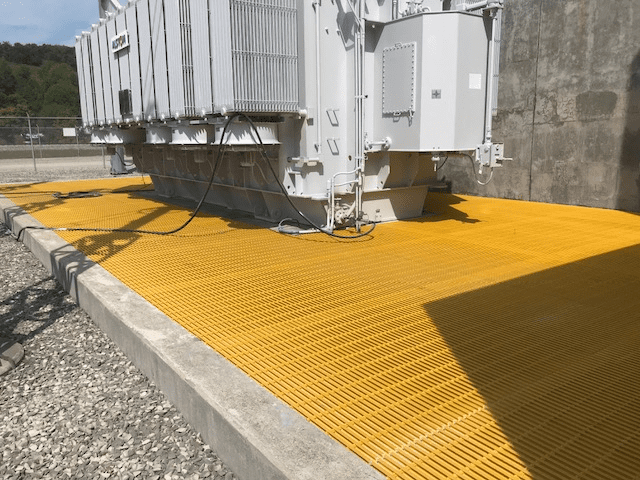

Unidirectional strength is maximized by mechanically locking bearing bars and cross rods. Pound for pound, FRP pultruded grating has the strength of steel at a fraction of the weight, plus it won’t corrode or rust like steel can.

Load-Bearing Strength

The continuous glass rovings added in the pultrusion process provide longitudinal strength and the capability to resist compression, tension and bending. At the same time, transverse strength and impact resistance are raised thanks to the continuous glass mat. The result is heavy-duty pultruded fiberglass grating that holds up under heavy weight and high traffic.

Excellent Traction

The FRP pultruded grating available through OSCO includes a quartz anti-slip epoxy coating. The grit it creates provides a safer and more secure walking surface.

Long Service Life

The resin system of the pultrusion process creates a coated resin surface that raises the resistance to chemical corrosion and continuous UV exposure. Pultruded fiberglass gratings can last for decades in applications where steel fails. OSCO’s lineup of FRP pultruded grating also meets the Class 1 Flame Spread Rating per ASTM E-84 test standards.

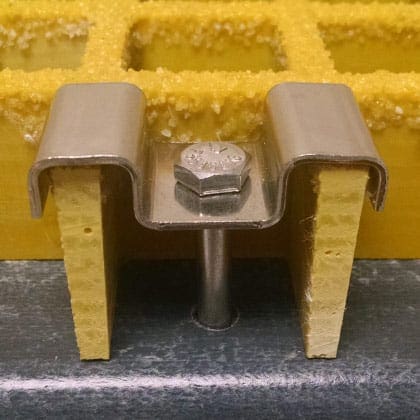

Easy To Install

Because FRP pultruded gratings from OSCO are lightweight, they’re easy to transport and move around the installation site. Only standard hand tools are needed to cut and fabricate the grating for a perfect fit — no welding or special skills are necessary.

Available Resin Systems

Resin systems establish the amount of corrosion protection in the pultruded fiberglass grating. OSCO’s selection includes two resin systems. Both provide corrosion resistance greatly superior to steel and meet Class 1 Flame Spread Rating per ASTM E-84 test standards.

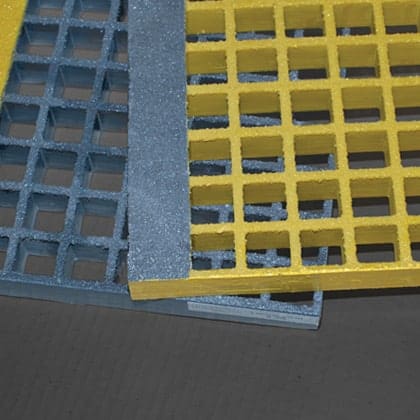

VFR: This vinylester resin system provides the highest level of corrosion protection. Available standard colors include yellow and gray.

IFR: This premium-grade isophthalic polyester resin system delivers excellent corrosion protection and is also available in yellow and gray.

Grating Panel Sizes*

- 3′ wide x 20′ long

- 3′ wide x 24′ long

- 4′ wide x 20′ long

- 4′ wide x 24′ long

*Dimensions are nominal. Not all panel sizes are stocked in every resin series and color.

Pultruded FRP Grating Options

Special orders are available for applications needing different colors or an even higher level of strength. Contact our knowledgeable team to get exactly what you need.

Related Products

Complete your project with these popular OSCO products.

Chemical Resistance Guide

Access chemical compatibility tables to view detailed data from resin manufacturers, including maximum allowable temperatures and concentrations.

Count On OSCO For All Your Safety Solutions

Along with pultruded fiberglass grating and FRP molded grating, OSCO is your complete resource for a variety of fiberglass-reinforced polymer (FRP) industrial safety products. Choose OSCO for ReadySeries materials, fiberglass stair treads, and other FRP structures. We’re also your one-stop shop for utility markers, cathodic protection testing systems, marking flags and vinyl safety signs and decals.

Ready to Get Started?

Whether you simply need to replace a part or have a major project to start from scratch, our knowledgeable, experienced team is here to help.

Contact Me Request a Quote